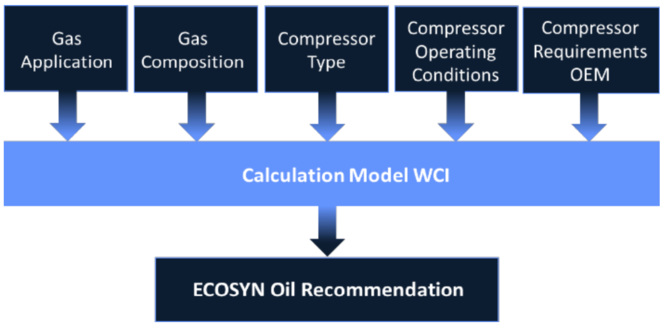

Every gas compressor needs a lubricant that is precisely tuned to its specific application. Whether you need to select a lubricant for a hydrocarbon gas, a process gas or an inert gas application, WCI can offer you the best lubricant solution.

One of the key concerns for hydrocarbon gas compression is dilution. WCI uses a tailor- made calculation program to calculate the amount of gases that will be dissolved in the lubrication oil and from this the resulting working viscosity at the bearings.

For process gas and inert gas applications it is the chemical reactivity of the gas with the lubricant that plays a major role. Our experienced chemists know the possible reactions between gas and lubricant components and the conditions under which they occur.

Our tailor-made program in combination with our oil analysis program and long term expertise in a very broad field of specialty gas applications, ensures:

This results in a higher operational production reliability throughout your plant.

WCI’s product line of ECOSYN synthetic gas compressor lubricants offers a complete range of chemistries to meet the needs of your rotary screw, rotary vane, reciprocating or centrifugal compressors for different types of gases and different types of applications.

Gases:

Applications:

Used for light to medium hydrocarbon gases. Good oxidation stability, especially if oxygen is present in the gas stream. High evaporation stability minimizes the oil carryover into the gas stream in comparison to standard mineral oils.

Used for light to medium hydrocarbon gases. Good oxidation stability, especially if oxygen is present in the gas stream. High evaporation stability minimizes the oil carryover into the gas stream in comparison to standard mineral oils.

Chemically inert polyalphaolefin based lubricants. Recommended for use with aggressive gases like ammonia, methylchloride or vinyl chloride. Low pour point to start the compressor at low oil temperatures. These lubricants are NSF H1, Kosher and Halal certified.

Chemically inert polyalphaolefin based lubricants. Recommended for use with aggressive gases like ammonia, methylchloride or vinyl chloride. Low pour point to start the compressor at low oil temperatures. These lubricants are NSF H1, Kosher and Halal certified.

Used for heavy hydrocarbon gases. High resistance to thinning out by hydrocarbon dilution. Contains additives to protect equipment from wear, H2S corrosion and rust. Low pour point for starting at low oil temperatures.

Used for heavy hydrocarbon gases. High resistance to thinning out by hydrocarbon dilution. Contains additives to protect equipment from wear, H2S corrosion and rust. Low pour point for starting at low oil temperatures.

Chemically inert to chemical gases of acidic nature. No metallic additives to interfere with catalytic processes. Increased resistance to varnish, carbon and acid formation.

Chemically inert to chemical gases of acidic nature. No metallic additives to interfere with catalytic processes. Increased resistance to varnish, carbon and acid formation.

Cleaning fluid for compressors: fast and effective cleaning. Releases contaminants and deposits from components.

Cleaning fluid for compressors: fast and effective cleaning. Releases contaminants and deposits from components.