The need for higher productivity and greater efficiency in operation, has placed severe demands on lubricants. These severe demands can no longer be met by mineral oil products in many applications. To meet these extreme demands on the lubricant, ECOSYN synthetic gear and bearing lubricants were developed.

The nature of a machine production environment influences the degree of effectiveness for a given bearing and gear lubricant type and grade. This environment can be: wet, dry, hot, cold, abrasive, dirty and with harsh chemical exposure, steady state or intermittent operation etc…

ECOSYN industrial gear and bearing lubricants are specifically formulated to meet the demanding requirements for open and sealed gearboxes and for bearings, including extreme pressure and food grade applications.

Our ECOSYN lubricants have:

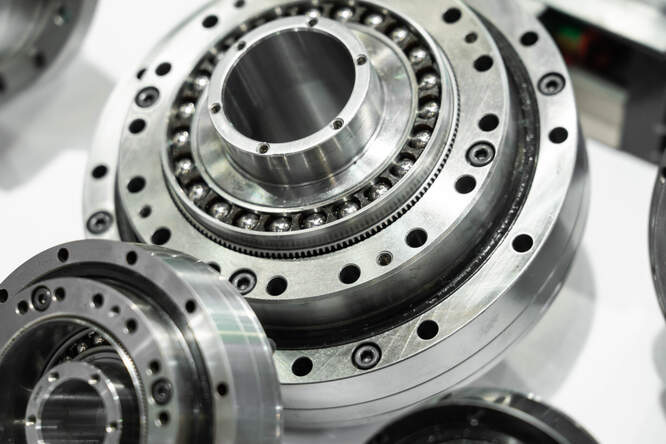

Lubricants for bearing and gear systems have to perform the general task of transferring forces, minimizing wear, reducing friction, dissipating heat and remove abrasive particles. Depending on the type of bearing or gear and the operating conditions, the lubricant has to meet various requirements. Therefore, it is crucial to select the right lubricant for each specific application.

As a result of our longterm tribology expertise in a very broad field of applications, our technical experts will offer you the best technical and cost effective solution for your gear or bearing application.

WCI’s product line of ECOSYN industrial gear and bearing lubricants offers a complete range of lubricants coupled with quality and reliability.

Synthetic bearing and gear oils with ashless anti-wear and antioxidants. These oils have been designed to provide proper lubrication under hydrodynamic and mild boundary lubrication conditions. They are recommended for gear and bearing systems where moderate loads and high temperatures are expected, including worm gears containing soft metals such as bronze, brass and copper.

Synthetic bearing and gear oils with ashless anti-wear and antioxidants. These oils have been designed to provide proper lubrication under hydrodynamic and mild boundary lubrication conditions. They are recommended for gear and bearing systems where moderate loads and high temperatures are expected, including worm gears containing soft metals such as bronze, brass and copper.

Extreme pressure and anti-wear gear oils intended for enclosed gears operating under adverse loads and temperatures. These are high quality, extreme pressure PAO gear oils offering exceptional performance in gears and other industrial applications.

Extreme pressure and anti-wear gear oils intended for enclosed gears operating under adverse loads and temperatures. These are high quality, extreme pressure PAO gear oils offering exceptional performance in gears and other industrial applications.

Food grade bearing and gear oils for extreme service conditions. Incidental Food Contact: FDA 21 CFR Title 21, 178.3570, NSF H-1; HACCP; DIN 51517 T.3

Food grade bearing and gear oils for extreme service conditions. Incidental Food Contact: FDA 21 CFR Title 21, 178.3570, NSF H-1; HACCP; DIN 51517 T.3

Energy efficient. High thermal stability. Recommended for the use in worm and hypoid gears and in a wide variety of other severe heavy-duty applications: enclosed gear units, highly loaded bearings, plain and roller contact bearings.

Energy efficient. High thermal stability. Recommended for the use in worm and hypoid gears and in a wide variety of other severe heavy-duty applications: enclosed gear units, highly loaded bearings, plain and roller contact bearings.