Choosing the best lubricant for your air compressor is not always easy with so many different product options out there. The major reason for selecting synthetic lubricants for air compressors is their stability in the presence of heat, air and moisture.

The oxygen in air reacts with hydrocarbon lubricants to form organic acids, carbon oxides, varnishes, sludge and hard carbon like deposits on valves, heads, discharge ports and piping. Water vapor can condense as the compressed air is cooled. This may cause corrosion, solubilize metals or form emulsions.

ECOSYN synthetic lubricants for rotary screw, rotary vane, reciprocating and centrifugal compressors, have been field proven to outperform key criteria for optimal compressor performance such as:

Other considerations for selecting synthetic ECOSYN lubricants are safety, reduced maintenance and the potential to reduce energy requirements.

Whether you need a lubricant for:

WCI’s application experts support you in selecting the right lubricant for your air compressor application.

WCI’s product line of ECOSYN synthetic air compressor lubricants offers a complete range of chemistries to meet the needs of your rotary screw, rotary vane, reciprocating or centrifugal compressors and to ensure long-term performance of your equipment.

Premium ester based lubricants with superior thermal and oxidative stability and no tendency to form sludge or varnish. Recommended for high temperature applications in flooded rotary screw compressors, rotary vane compressors, and reciprocating compressors.

Premium ester based lubricants with superior thermal and oxidative stability and no tendency to form sludge or varnish. Recommended for high temperature applications in flooded rotary screw compressors, rotary vane compressors, and reciprocating compressors.

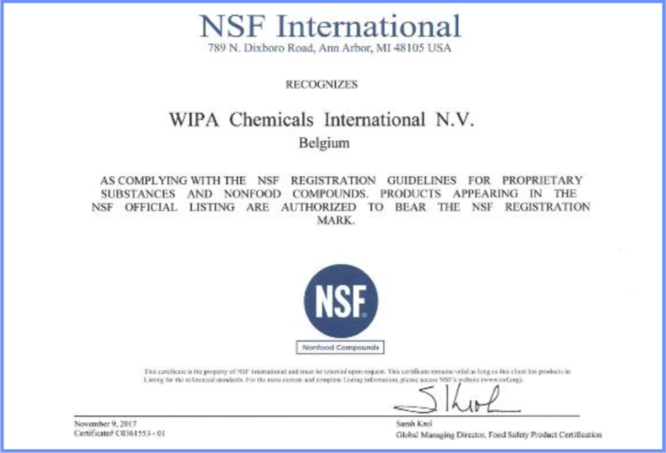

NSF H1, Kosher and Halal registered polyalphaolefin and food grade ester lubricants with superior oxidative stability and resistance to sludge and varnish. Recommended for use in compressors with incidental food contact requirements.

NSF H1, Kosher and Halal registered polyalphaolefin and food grade ester lubricants with superior oxidative stability and resistance to sludge and varnish. Recommended for use in compressors with incidental food contact requirements.

Premium ester based lubricants with superior oxidative and thermal stability, antiwear protection and no tendency to form sludge or varnish. Recommended for use in high temperature flooded rotary screw compressors.

Premium ester based lubricants with superior oxidative and thermal stability, antiwear protection and no tendency to form sludge or varnish. Recommended for use in high temperature flooded rotary screw compressors.